Solar Panels

Technology : Mono & Poly Crystalline Technology Panels

Panels are powered by next generation 5-6 bus bar crystalline full cells and half cut cells . The 6 bus bar cells provide higher efficiency with lower series resistance and also help with lower operating temperatures ensuring higher outputs from the module. The cells are engineered for high performance under a wide spectrum of lights ensuring good outputs under low light conditions The next generation cells clubbed with premium materials and superior manufacturing techniques ensure a module that outperforms most in the industry

Advantages : These Mono & Poly-Crystalline- Positive tolerance panels which is built with the best standard art of construction and with all major approvals and certifications.

Manufacturing Process : The automated stringers ensure consistent stringing of all the cells and combined with the automatic layup, result in the precise handling of the strings. This inturn leads to better space utilization and aesthetics of the module. The automated lamination cycle guanrantees that there are no air bubbles in the module and premium adhesion of the protectants thus ensuring the longer life of the module.

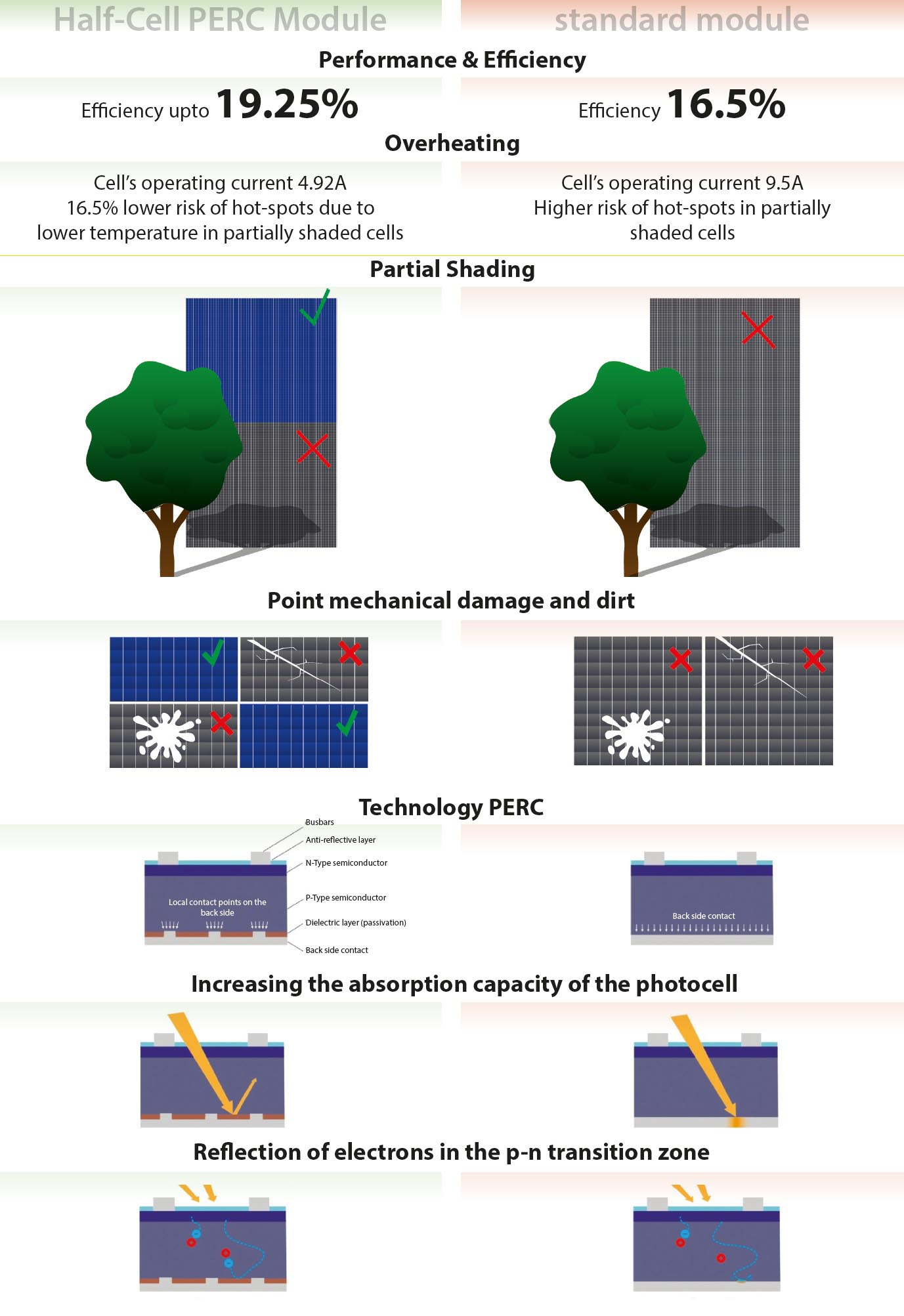

Updated Mono and Poly Crystalline – PERC Cells

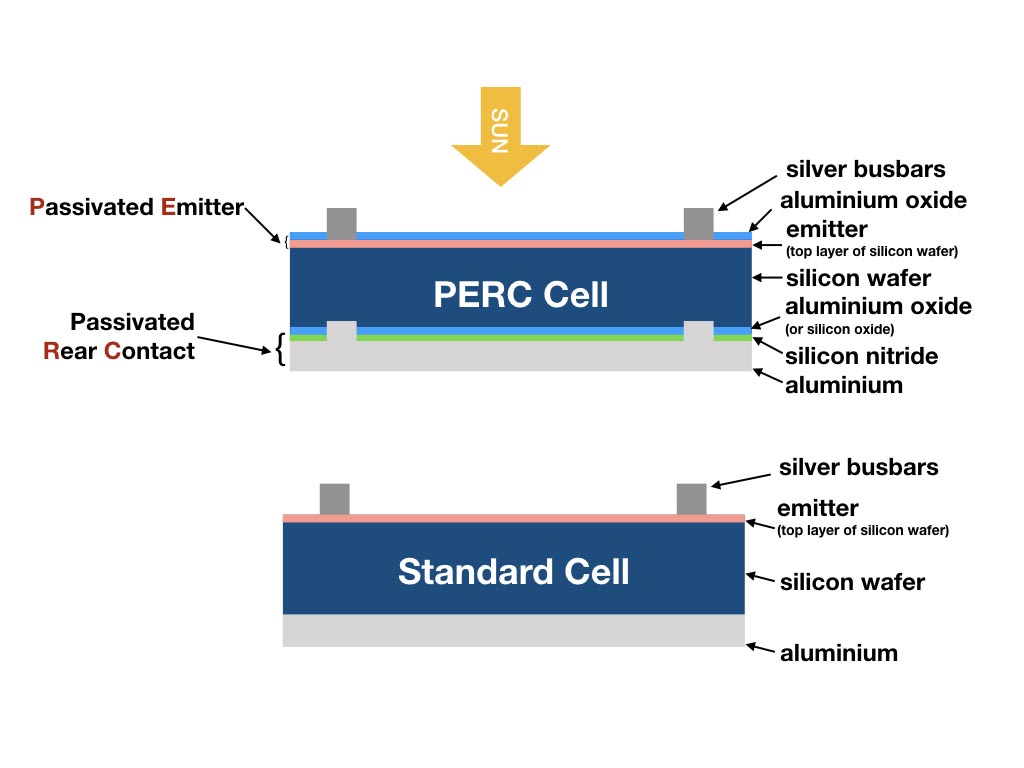

PERC stands for Passivated Emitter and Rear Cell. You also find the term Passivated Emitter and Rear Contact.

The objective of scientists being to get the most of electrons out of the solar cells, the PERC architecture essentially enables to improve light capture near the rear surface and to optimize electrons capture.